Understanding Glass Patio Table Leg Connectors: A Comprehensive Guide

Glass patio tables offer an elegant and modern aesthetic to outdoor spaces. However, their construction relies heavily on the integrity of the leg connectors. These connectors are critical components that ensure the stability and longevity of the table. Understanding the different types of connectors, the materials used in their construction, and the factors that influence their performance is essential for anyone purchasing, assembling, or maintaining a glass patio table.

The primary function of a glass patio table leg connector is to securely attach the table legs to the glass tabletop. This connection must be robust enough to withstand the weight of the glass, as well as any additional items placed on the table. Furthermore, it needs to resist environmental stressors such as wind, rain, and temperature fluctuations, which can degrade the connectors over time. The design and material composition of the connector directly impact its ability to fulfill these requirements.

Types of Glass Patio Table Leg Connectors

Glass patio table leg connectors come in various designs, each with its own advantages and disadvantages. The selection of the appropriate connector type depends on factors such as the table's overall design, the intended use of the table, and the environmental conditions it will be exposed to. Here's a breakdown of some common types:

Bolt-Through Connectors: These are among the most common and straightforward types of connectors. They typically consist of a metal plate with pre-drilled holes that align with corresponding holes in the table legs. Bolts are then passed through these holes and tightened, clamping the glass tabletop between the legs and the connector plate. The advantage of bolt-through connectors lies in their simplicity and the strong, direct connection they provide. However, the glass must be pre-drilled, which can be a delicate process and requires precision manufacturing. Furthermore, overtightening the bolts can lead to cracking or shattering of the glass.

Adhesive Connectors: As the name suggests, these connectors rely on specialized adhesives to bond the table legs to the glass tabletop. The adhesive is typically a high-strength epoxy or polyurethane-based compound that is specifically designed for glass-to-metal adhesion. Adhesive connectors offer a clean, seamless appearance, as there are no visible bolts or fasteners. They also eliminate the need for drilling the glass, which reduces the risk of damage. However, the success of adhesive connectors hinges on the quality of the adhesive, the surface preparation of the glass and leg materials, and the application technique. Improper application or the use of substandard adhesive can lead to premature failure and detachment of the legs.

Suction Cup Connectors: These connectors utilize suction cups to create a temporary or semi-permanent bond between the table legs and the glass tabletop. They are often used in lightweight or portable glass tables where easy assembly and disassembly are desirable. Suction cup connectors offer the advantage of being non-invasive, as they do not require drilling or adhesives. However, their load-bearing capacity is significantly lower than that of bolt-through or adhesive connectors. They are also more susceptible to detachment due to changes in temperature, humidity, or surface contamination. Suction cup connectors are generally not suitable for heavy-duty or permanent glass patio table installations.

Clamping Connectors: Clamping connectors employ a mechanical clamping mechanism to secure the table legs to the glass tabletop. These connectors typically consist of a two-part assembly that sandwiches the glass between them. One part is attached to the table leg, while the other part applies pressure to the glass surface through a tightening screw or cam lever. Clamping connectors offer a balance between ease of installation and load-bearing capacity. They do not require drilling or adhesives and can be adjusted to accommodate different glass thicknesses. However, they can be more visually obtrusive than adhesive connectors and may require periodic tightening to maintain their grip on the glass.

Integrated Frame Connectors: Some glass patio tables feature an integrated frame that provides a structural foundation for the glass tabletop. The table legs are then attached to this frame using various methods, such as bolting, welding, or snap-fit connections. Integrated frame connectors offer a high degree of stability and load-bearing capacity, as the frame distributes the weight evenly across the table legs. However, they can be more complex and expensive to manufacture than other types of connectors. Integrated frame connectors are typically found in high-end glass patio tables.

Materials Used in Glass Patio Table Leg Connectors

The choice of material for glass patio table leg connectors is crucial for their durability and resistance to environmental factors. Different materials offer varying levels of strength, corrosion resistance, and aesthetic appeal. The most common materials used in connector construction include:

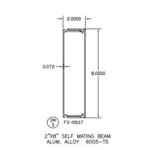

Aluminum: Aluminum is a popular choice for patio furniture due to its lightweight, corrosion resistance, and recyclability. Aluminum connectors are typically made from aluminum alloys that have been treated to enhance their strength and resistance to oxidation. Anodizing is a common surface treatment that creates a protective oxide layer on the aluminum, further improving its corrosion resistance and appearance. Aluminum connectors are well-suited for outdoor environments, especially those with moderate humidity and rainfall.

Stainless Steel: Stainless steel offers superior corrosion resistance compared to aluminum, making it an ideal material for patio furniture that is exposed to harsh weather conditions, such as coastal environments or areas with high levels of air pollution. Stainless steel connectors are typically made from 304 or 316 grade stainless steel, which contain chromium and nickel to provide excellent resistance to rust and staining. Stainless steel connectors are durable, aesthetically pleasing, and require minimal maintenance. However, they are generally more expensive than aluminum connectors.

Steel: Steel connectors are strong and durable but are susceptible to corrosion if not properly treated. Steel connectors are typically coated with a protective finish, such as powder coating or galvanizing, to prevent rust. Powder coating involves applying a dry, free-flowing powder electrostatically to the steel surface and then curing it with heat to create a tough, durable finish. Galvanizing involves coating the steel with a layer of zinc, which provides sacrificial protection against corrosion. Steel connectors are a cost-effective option for patio furniture, but they require regular maintenance to prevent rust and extend their lifespan.

Plastic/Polymer: Plastic or polymer connectors are often used in lightweight or budget-friendly glass patio tables. These connectors are typically made from high-density polyethylene (HDPE) or polypropylene (PP), which are durable, weather-resistant plastics. Plastic connectors are lightweight, easy to mold into complex shapes, and resistant to corrosion. However, they are generally not as strong or durable as metal connectors. Plastic connectors are best suited for indoor or covered outdoor environments where they are not exposed to extreme temperatures or heavy loads.

Factors Affecting the Performance of Glass Patio Table Leg Connectors

The performance of glass patio table leg connectors is influenced by several factors, including the quality of the materials, the design of the connector, the assembly process, and the environmental conditions. Understanding these factors is essential for ensuring the longevity and stability of the table.

Material Quality: The quality of the materials used in connector construction directly impacts their strength, durability, and resistance to corrosion. Using high-quality metals, such as stainless steel or treated aluminum, will significantly extend the lifespan of the connectors and ensure their ability to withstand environmental stressors. Similarly, using high-strength adhesives or durable plastics will improve the overall performance of the connectors.

Connector Design: The design of the connector plays a crucial role in its ability to distribute weight evenly and resist stress concentrations. A well-designed connector will provide a secure and stable connection between the table legs and the glass tabletop, minimizing the risk of failure. Factors such as the shape, size, and thickness of the connector, as well as the placement of bolts or adhesive surfaces, can all influence its performance.

Assembly Process: Proper assembly is essential for ensuring the integrity of the connection between the table legs and the glass tabletop. Following the manufacturer's instructions carefully and using the correct tools and techniques will help to prevent damage to the glass or the connectors. For example, overtightening bolts can crack the glass, while improper adhesive application can lead to detachment of the legs. The assembly process should be carried out by someone with experience and attention to detail.

Environmental Conditions: The environmental conditions to which the glass patio table is exposed can significantly impact the performance of the connectors. Exposure to extreme temperatures, humidity, sunlight, and air pollution can accelerate the degradation of the materials and weaken the connection. Choosing connectors that are specifically designed for outdoor use and protecting the table from harsh weather conditions will help to extend its lifespan.

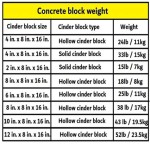

Load Capacity: The load capacity of the connector must be adequate for the intended use of the table. Overloading the table can put excessive stress on the connectors, leading to failure. The manufacturer's specifications for the maximum weight capacity of the table should be carefully observed. Furthermore, consideration should be given to the potential for uneven weight distribution, which can concentrate stress on certain connectors.

Maintenance: Regular maintenance can help to prevent premature failure of the connectors. This may include cleaning the connectors to remove dirt and debris, tightening loose bolts, and applying protective coatings to prevent corrosion. Inspecting the connectors regularly for signs of damage or wear and tear can also help to identify potential problems before they become major issues.

By considering these factors, individuals can make informed decisions about the selection, assembly, and maintenance of glass patio table leg connectors, ensuring the longevity and stability of their outdoor furniture.

Try To Source A Part For My Patio Table Repair Hometalk

Try To Source A Part For My Patio Table Repair Hometalk

Samsonite Patio Furniture Replacement Slings

Samsonite Patio Furniture Replacement Slings

Samsonite Patio Furniture Replacement Slings

How To Repair Glass Patio Table Problems

Kadyn Side Table Dining 28 5 Inch Outdoor Patio Square Glass Top With Rattan Edging

Pelham Bay Glass Patio Tables At Com

How To Repair Glass Patio Table Problems

Wellfor 28 In H Black Round Metal Outdoor Bistro Table With Tempered Glass Top And Umbrella Hole Op Hwy 70488 The Home Depot

Related Posts