Prefab Patio Decks: A Comprehensive Guide

Prefabricated patio decks, or "prefab patio decks," offer a compelling alternative to traditional stick-built decks. These decks are constructed in a controlled factory environment and then transported to the building site for installation. This approach presents distinct advantages and disadvantages compared to conventional deck construction, making it crucial to understand the nuances before making a decision. This article aims to provide a comprehensive overview of prefab patio decks, covering their benefits, drawbacks, material options, installation processes, and cost considerations.

Advantages of Prefab Patio Decks

Prefabricated patio decks offer several key advantages that contribute to their growing popularity. These advantages primarily revolve around speed of construction, quality control, and potential cost savings.

One of the most prominent advantages is the significantly reduced construction time. Because the majority of the deck building process occurs in a factory, the on-site installation is greatly simplified and accelerated. This eliminates weather-related delays and minimizes disruption to the homeowner's property. A prefab deck can often be installed in a matter of days, compared to weeks for a traditional deck build. The pre-engineered nature of prefab decks also streamlines the permitting process in many jurisdictions, further reducing the overall project timeline.

Furthermore, the controlled factory environment allows for enhanced quality control. Manufacturing processes are standardized and monitored closely, minimizing the potential for errors that can occur during on-site construction. Materials are stored and handled properly, preventing damage or degradation due to exposure to the elements. This meticulous attention to detail results in a deck with superior structural integrity and a more consistent finish. The precision achieved in a factory setting is difficult to replicate with on-site construction, where carpenters must contend with varying weather conditions and potential inconsistencies in materials.

Cost savings can also be a significant factor in choosing a prefab patio deck. While the initial cost of the deck materials may be comparable to traditional decking, the reduced labor costs associated with faster installation can result in overall savings. The pre-engineered design also minimizes material waste, which further contributes to cost efficiency. Additionally, the improved quality control and durability of prefab decks can translate into lower long-term maintenance costs, as they are less prone to issues such as warping, cracking, or rot.

Disadvantages of Prefab Patio Decks

Despite the numerous advantages, prefab patio decks also present certain limitations that should be carefully considered. These limitations primarily involve design flexibility, site accessibility, and potential transportation challenges.

One of the most significant drawbacks is the limited design flexibility. Prefab decks are typically offered in a range of standard sizes and configurations, which may not perfectly suit every homeowner's needs or preferences. Customization options are often restricted, which can be a concern for those seeking a unique or highly personalized deck design. While some manufacturers offer limited modifications, the extent of customization is generally less than that available with traditional deck building. Homeowners with irregular property lines, specific aesthetic requirements, or unusual site conditions may find that prefab decks do not offer the necessary design versatility.

Site accessibility can also pose a challenge. Prefab decks are typically delivered to the site in large sections or as a complete unit, requiring sufficient access for trucks and cranes. Narrow driveways, steep slopes, or obstructions such as trees and power lines can hinder the delivery and installation process. In some cases, modifications to the landscape or the use of specialized equipment may be necessary to overcome these accessibility challenges. It is crucial to assess the site conditions carefully before committing to a prefab deck to ensure that delivery and installation are feasible.

Transportation costs and logistical challenges can also be a consideration. The cost of transporting a large, prefabricated deck can be substantial, especially for long distances. Furthermore, ensuring that the deck arrives on site undamaged requires careful planning and execution. Proper packaging and handling are essential to prevent scratches, dents, or other forms of damage during transit. Delays or complications in the transportation process can also impact the overall project timeline and potentially increase costs.

Material Options for Prefab Patio Decks

The materials used in prefab patio decks are similar to those used in traditional decks, with a focus on durability, weather resistance, and aesthetic appeal. The most common material options include wood, composite, and aluminum.

Wood remains a popular choice for its natural beauty and warmth. Pressure-treated lumber is often used for the framing and substructure, providing resistance to decay and insect infestation. For the decking surface, popular options include cedar, redwood, and tropical hardwoods like ipe. Cedar and redwood are known for their natural resistance to rot and insects, while ipe is prized for its exceptional durability and rich color. However, wood decks require regular maintenance, including cleaning, staining, and sealing, to protect them from the elements and prevent deterioration.

Composite decking has gained significant popularity as a low-maintenance alternative to wood. Composite decks are typically made from a blend of recycled plastic and wood fibers, offering excellent durability and resistance to moisture, insects, and fading. Composite decking is available in a wide range of colors and textures, mimicking the look of natural wood without the need for staining or sealing. While composite decking can be more expensive than wood upfront, its lower maintenance requirements can result in long-term cost savings. However, some composite decking materials can be prone to scratching or staining, and they may not have the same natural aesthetic appeal as wood.

Aluminum decking is another durable and low-maintenance option. Aluminum decks are lightweight, corrosion-resistant, and require minimal upkeep. Aluminum decking is often used in coastal environments or other areas with high humidity or exposure to saltwater. Aluminum decks are also fire-resistant, making them a safe choice for areas prone to wildfires. However, aluminum decking can be more expensive than wood or composite decking, and it may not have the same aesthetic appeal for some homeowners. The surface of aluminum decks can also become hot in direct sunlight, requiring the use of specialized coatings or coverings.

Installation Process of Prefab Patio Decks

The installation process for prefab patio decks is generally faster and simpler than that for traditional decks, but it still requires careful planning and execution. The process typically involves site preparation, foundation installation, deck assembly, and finishing touches.

Site preparation is a crucial first step. This typically involves clearing the area where the deck will be installed, leveling the ground, and ensuring proper drainage. Any existing vegetation or debris should be removed, and the soil should be compacted to provide a stable base for the deck. Proper site preparation is essential to prevent settling or shifting of the deck over time.

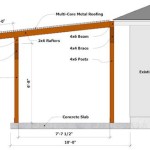

Foundation installation is the next step. Depending on the type of deck and the soil conditions, the foundation may consist of concrete piers, posts, or a combination of both. The foundation must be properly aligned and leveled to ensure that the deck is structurally sound. In some cases, a building permit may be required for the foundation, so it is essential to check with local building authorities. The foundation provides the necessary support for the deck and prevents it from sinking or shifting over time.

Deck assembly is the core of the installation process. The prefabricated deck sections are typically delivered to the site and then lifted into place using a crane or other equipment. The sections are then secured to the foundation using bolts or other fasteners. The assembly process is generally straightforward, but it requires careful attention to detail to ensure that the sections are properly aligned and connected. The pre-engineered design of prefab decks simplifies the assembly process, reducing the risk of errors and ensuring a consistent result.

Finishing touches complete the installation. This may involve installing railings, stairs, and other accessories. The deck surface may also need to be cleaned and sealed to protect it from the elements. Any necessary electrical work, such as installing lighting or outlets, should also be completed at this stage. The finishing touches enhance the functionality and aesthetic appeal of the deck, making it a comfortable and enjoyable outdoor space.

Cost Considerations for Prefab Patio Decks

The cost of a prefab patio deck can vary depending on several factors, including the size of the deck, the materials used, the complexity of the design, and the location of the installation. It is essential to obtain multiple quotes from different manufacturers and installers to compare prices and ensure that the quote includes all necessary costs.

The cost of the deck materials is a significant factor. Wood decks are generally less expensive than composite or aluminum decks, but they require more maintenance. Composite decks offer a good balance of durability and cost, while aluminum decks are the most expensive but also the most durable and low-maintenance. The choice of material will depend on the homeowner's budget, aesthetic preferences, and long-term maintenance considerations.

Installation costs can also vary depending on the complexity of the project. Prefab decks typically have lower installation costs than traditional decks due to the faster and simpler installation process. However, factors such as site accessibility, foundation requirements, and the need for specialized equipment can affect the installation costs. It is essential to obtain a detailed quote from the installer that includes all labor costs, equipment rental fees, and any other associated expenses.

Other costs to consider include permits, transportation, and site preparation. Building permits are typically required for deck construction, and the cost of the permit can vary depending on the location. Transportation costs can be substantial for large prefab decks, especially for long distances. Site preparation costs can also vary depending on the condition of the site and the amount of work required to prepare it for the deck installation. It is essential to factor in all of these costs when budgeting for a prefab patio deck.

14 Backyard Deck Ideas To Upgrade Your Outdoor Space

Versadeck Modular Decking Deck Panels For Decks Easy Designs

Prefab Deck Kit Econodek

Outdoor Swimming Pool Patio Decks Sunshading Prefab Houses Garden Buildings Balcony Awnings Louvre Roof Gazebo Shelters Motorized Pergola Tent China Made In Com

Floating Deck Ideas The Home Depot

Photo 6 Of In 5 Prefab Deck Kit Companies To Easily Upgrade Your Backyard Patio

Udecx 10 Ft X 100 Sq Red Cedar Patio Deck Starter Kit Rskw31 The Home Depot

15 Gorgeous Deck And Patio Ideas You Can Diy Family Handyman

The Turbulent Trajectory Of Decks And Outdoor Living Builder

Outdoor Swimming Pool Patio Decks Sunshading Prefab Houses Garden Buildings Balcony Awnings Louvre Roof Gazebo Shelters Motorized Pergola Tent China Made In Com