How To Make A Concrete Patio Flooring

Concrete patios offer a durable, versatile, and aesthetically pleasing outdoor living space. Creating a concrete patio involves careful planning, precise execution, and a thorough understanding of the materials and techniques involved. This article provides a comprehensive guide to constructing a concrete patio, covering the essential steps from site preparation to finishing the concrete surface.

Planning and Preparation: Laying the Groundwork for Success

Before commencing any physical work, a detailed plan is crucial. This plan ensures the patio fulfills the intended purpose, complements the surrounding landscape, and adheres to any relevant building codes and regulations. The planning stage involves assessing the site, determining the patio's size and shape, and selecting the appropriate concrete mix and finishing techniques.

First, accurately assess the location. Consider factors such as sun exposure, drainage, proximity to the house, and existing vegetation. The patio should be located in an area that receives adequate sunlight, is well-drained to prevent water accumulation, and is easily accessible from the house. Furthermore, the location should be free of obstructions such as tree roots, underground utilities, and significant slopes.

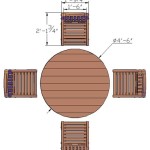

Next, determine the size and shape of the patio. The dimensions should be proportional to the size of the yard and the intended use of the space. A small patio might suffice for a couple of chairs and a small table, while a larger patio could accommodate a dining set, lounge furniture, and a barbecue grill. Consider the flow of traffic between the patio and other areas of the yard, as well as the overall aesthetic appeal of the design.

Once the size and shape are determined, obtain any necessary permits. Local building codes often require permits for concrete patios, especially if they exceed a certain size or are located close to property lines. Contact the local building department to inquire about permit requirements and any applicable regulations.

Finally, order the necessary materials. This includes concrete mix, forms, reinforcement (such as rebar or wire mesh), gravel base material, edging, and any tools and equipment that will be required. Accurately estimate the quantity of each material based on the patio's size and thickness, and order slightly more than needed to account for waste or unexpected changes.

Construction: From Excavation to Pouring the Concrete

With the planning stage complete, the next phase involves the physical construction of the patio. This includes excavating the site, building the forms, installing the base material and reinforcement, and finally, pouring and leveling the concrete.

Begin by excavating the site to the required depth. Typically, the excavation should be 4 to 6 inches deep, depending on the desired thickness of the concrete slab and the underlying base material. Remove all vegetation, topsoil, and any other debris from the excavation area. Use a shovel and a wheelbarrow to remove the excavated material, and dispose of it properly.

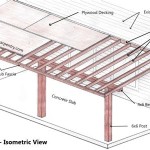

Next, construct the forms around the perimeter of the excavation. The forms will serve as a mold for the concrete and will ensure that the patio has the desired shape and dimensions. Use lumber, such as 2x4s or 2x6s, to build the forms. Ensure that the forms are level and square, and that they are securely fastened together using screws or nails. Use stakes to support the forms and prevent them from bowing or shifting during the concrete pour.

After the forms are in place, install the base material. The base material provides a stable and well-drained foundation for the concrete slab. Use gravel or crushed stone as the base material, and spread it evenly over the excavation area. Compact the base material using a plate compactor or a hand tamper to create a solid and level surface. The base material should be at least 4 inches thick.

Install reinforcement to enhance the strength and durability of the concrete. Rebar or wire mesh can be used as reinforcement. Rebar is typically used for thicker slabs, while wire mesh is suitable for thinner slabs. Space the reinforcement according to the recommendations of a structural engineer or a concrete expert. Secure the reinforcement in place using chairs or spacers to ensure that it is properly positioned within the concrete slab.

Now, prepare for the concrete pour. Ensure that all necessary tools and equipment are readily available, including a concrete mixer, a wheelbarrow, shovels, rakes, floats, trowels, and a bull float. Protect any nearby surfaces that could be damaged by the concrete, such as siding or landscaping. Have a sufficient number of people available to assist with the concrete pour, as it can be a physically demanding task.

Begin pouring the concrete into the forms. Start at one end of the patio and work your way to the other end. Pour the concrete in layers, ensuring that each layer is thoroughly consolidated to eliminate air pockets and voids. Use a shovel or a rake to spread the concrete evenly within the forms. Be careful not to disturb the forms or the reinforcement during the concrete pour.

Once the concrete is poured, use a bull float to level the surface. The bull float is a large, flat tool that is used to smooth out the concrete and remove any bumps or irregularities. Overlap each pass with the bull float to ensure a smooth and even surface. Work the bull float in both directions to eliminate any high or low spots.

Finishing and Curing: Achieving a Long-Lasting, Aesthetically Pleasing Surface

The final stage of concrete patio construction involves finishing the surface and curing the concrete. Finishing refers to the techniques used to create the desired texture and appearance, while curing refers to the process of keeping the concrete moist to allow it to properly hydrate and gain strength.

After leveling the concrete with the bull float, allow the surface to bleed. Bleeding is the process by which excess water rises to the surface of the concrete. Wait until the bleed water has evaporated before proceeding with the finishing process. The amount of time it takes for the concrete to bleed depends on factors such as the weather conditions and the concrete mix. A general rule is to wait until the sheen of water disappears from the surface.

Once the bleed water has evaporated, begin the finishing process. There are many different finishing techniques that can be used to create a variety of textures and appearances. Some common finishing techniques include floating, troweling, and broom finishing.

Floating involves using a hand float or a magnesium float to compact the surface of the concrete and eliminate any small irregularities. Floating also helps to bring the paste to the surface, which is essential for achieving a smooth and durable finish. Work the float in a circular motion, overlapping each pass to ensure a consistent texture.

Troweling involves using a steel trowel to create a smooth, hard surface. Troweling is typically done after floating, and it is used to refine the surface and eliminate any remaining imperfections. Hold the trowel at a slight angle and work it in overlapping strokes. Apply light pressure to avoid creating trowel marks.

Broom finishing involves using a broom to create a textured surface. Broom finishing is a popular choice for patios because it provides slip resistance and a rustic appearance. Drag the broom across the surface of the concrete in a straight line, overlapping each pass to ensure a consistent texture. Choose a broom with the desired bristle stiffness to achieve the desired texture.

After finishing the surface, the concrete must be properly cured to ensure that it reaches its full strength and durability. Curing involves keeping the concrete moist for a period of several days or weeks. This can be achieved by covering the concrete with plastic sheeting, burlap, or wet sand. Regularly wet the covering material to keep the concrete moist.

Alternatively, a curing compound can be applied to the surface of the concrete. Curing compounds are liquid solutions that form a waterproof membrane on the surface of the concrete, preventing moisture from evaporating. Apply the curing compound according to the manufacturer's instructions. The curing period typically lasts for at least seven days, but longer curing periods are recommended for optimal strength and durability.

Once the concrete has been cured, remove the forms. Carefully pry the forms away from the concrete, being careful not to damage the edges of the patio. Backfill around the edges of the patio with soil or gravel to provide support and prevent erosion. Seal the concrete surface with a concrete sealer to protect it from water damage, stains, and wear and tear. Apply the sealer according to the manufacturer's instructions.

How To Make A Concrete Patio Bigger

How To Create Faux Tile Look On Concrete Patio Southern Hospitality

Easy Concrete Patio Coverup Ideas The Garden Glove

Diy Concrete Patio In 8 Easy Steps How To Pour A Cement Slab

5 Ways To Upgrade Your Concrete Patio

Diy Cement Tile Concrete Patio Southern Revivals

Quikrete Building A Concrete Patio

13 Great Diy Outdoor Patio Flooring Ideas On A Budget The Garden Glove

How To Create Faux Tile Look On Concrete Patio Southern Hospitality

Everything You Need To Know About Outdoor Concrete Resin Flooring Sureset Systems