How To Make A Wood Patio Table Top

Creating a custom wood patio table top can be a rewarding project that allows for personalization and tailored functionality for an outdoor space. Whether replacing a damaged tabletop or designing a new patio table from scratch, understanding the process and selecting the right materials are crucial for a durable and aesthetically pleasing outcome.

This article provides a comprehensive guide to crafting a wooden patio table top, covering material selection, construction techniques, finishing options, and essential considerations for longevity in an outdoor environment. The information presented aims to equip individuals with the knowledge necessary to confidently undertake this woodworking project.

Choosing the Right Wood for Your Patio Table Top

The selection of wood is the most critical factor influencing the lifespan and appearance of a patio table top. Wood intended for outdoor use must withstand exposure to the elements, including sunlight, rain, temperature fluctuations, and humidity. Certain wood species possess inherent properties that make them more suitable for outdoor applications.

Hardwoods:

Hardwoods are generally denser and more durable than softwoods, making them a desirable choice for patio furniture. Popular hardwood options for outdoor projects include:Teak:

Teak is highly prized for its natural oils, which provide exceptional resistance to moisture, decay, and insects. It is a durable and stable wood, making it an excellent choice for outdoor furniture. However, teak is typically more expensive than other wood options.Ipe:

Ipe, also known as Brazilian Walnut, is an exceptionally dense and durable hardwood. It is highly resistant to rot, decay, and insects, making it suitable for long-term outdoor use. Ipe is extremely hard and can be challenging to work with, requiring specialized tools and techniques.Cedar:

Cedar is naturally resistant to decay and insects due to its aromatic oils. It is a lightweight and relatively stable wood, making it easier to work with than hardwoods like teak or ipe. Western Red Cedar is a common choice for outdoor projects.Mahogany:

Mahogany is a durable hardwood with a rich color and attractive grain pattern. It is moderately resistant to decay and insects, but it benefits from regular sealing and maintenance.White Oak:

White oak is a strong and durable hardwood that is naturally water-resistant due to its closed-grain structure. It is a good option for outdoor projects, provided it is properly sealed and maintained.

Softwoods:

While hardwoods are generally preferred, certain softwoods can be used for patio table tops if properly treated and maintained.Pressure-Treated Pine:

Pressure-treated pine is softwood that has been chemically treated to resist decay and insects. It is a cost-effective option for outdoor projects. However, it can be prone to warping and cracking if not properly sealed and maintained. It also has a distinctive greenish tint from the treatment process, which may not be aesthetically desirable for all projects.

Consider the aesthetic qualities of each wood species, such as color, grain pattern, and texture, to ensure it aligns with the desired design aesthetic. Cost, availability, and workability are also important factors to consider when selecting the appropriate wood for the patio table top.

Construction Techniques for a Durable Table Top

Once the wood is selected, the construction techniques employed play a critical role in the structural integrity and longevity of the patio table top. Proper joinery and assembly methods are essential to withstand the stresses of outdoor use.

Planning and Design:

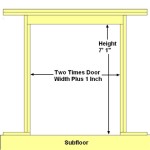

Begin by creating a detailed plan or sketch of the table top, including dimensions, shape, and edge details. Determine the number and width of the boards required to achieve the desired size. Consider the overall aesthetic and functionality of the table.Milling and Preparation:

Ensure all boards are planed to a consistent thickness and width. This will create a uniform surface and facilitate accurate joinery. Use a jointer to create straight and square edges on each board.Joinery Options:

Several joinery methods can be used to connect the boards that comprise the table top. The choice of joinery will depend on the desired aesthetic, skill level, and available tools.Butt Joints with Fasteners:

This is the simplest joinery method, where the edges of the boards are butted together and fastened with screws or nails. While straightforward, butt joints are the weakest type of joint and can be prone to failure over time, especially in outdoor conditions. It is recommended to reinforce butt joints with additional support, such as cleats or breadboard ends.Edge-to-Edge Glue Joints:

Edge-to-edge glue joints involve applying glue to the edges of the boards and clamping them together until the glue dries. This creates a stronger and more seamless joint than butt joints. Use a high-quality waterproof wood glue specifically designed for outdoor use. Ensure the edges are perfectly straight and square for a tight and uniform glue line.Tongue-and-Groove Joints:

Tongue-and-groove joints provide a mechanical interlock between the boards, increasing the strength and stability of the table top. This type of joint requires specialized tools, such as a router or table saw with a tongue-and-groove cutter set.Biscuit Joints:

Biscuit joints use small, oval-shaped biscuits inserted into slots cut into the edges of the boards. The biscuits expand when glued, creating a strong and aligned joint. A biscuit joiner is required to cut the slots.Mortise-and-Tenon Joints:

Mortise-and-tenon joints are a traditional woodworking technique that involves creating a projecting tenon on one board that fits into a corresponding mortise (hole) on the adjacent board. This is a strong and durable joint, but it requires precise cutting and fitting. Mortise-and-tenon joints are often used for attaching aprons or legs to the table top.

Assembly and Clamping:

Once the chosen joinery method is prepared, apply glue to the joints and clamp the boards together. Use clamps strategically to ensure even pressure and a flat, uniform surface. Allow the glue to dry completely according to the manufacturer's instructions.Reinforcement:

ConsiderAdding reinforcement to the underside of the table top to prevent warping or sagging, especially for larger tabletops. Attach cleats made from the same wood as the tabletop perpendicular to the grain of the tabletop boards. The cleats will provide additional support and prevent the boards from cupping over time. Use screws and glue to attach the cleats securely.Edge Treatment:

The edges of the table top can be shaped or finished in various ways. Options include rounding over the edges with a router, adding a chamfer, or applying edge banding. Consider the aesthetic and safety aspects of the edge treatment. Rounding over the edges can make the table top more comfortable to lean on and reduce the risk of splinters.Finishing and Protecting the Wood Patio Table Top

The final step in creating a wood patio table top is to apply a protective finish that will enhance its appearance and protect it from the elements. The choice of finish will depend on the desired aesthetic, the type of wood used, and the level of protection required.

Sanding:

Before applying any finish, thoroughly sand the table top to create a smooth and even surface. Start with a coarse grit sandpaper (e.g., 80-grit) to remove any imperfections or blemishes, then gradually progress to finer grits (e.g., 120-grit, 180-grit, 220-grit) to achieve a polished finish. Always sand in the direction of the wood grain.Cleaning:

After sanding, remove all dust and debris from the table top using a tack cloth or a vacuum cleaner with a brush attachment. Ensure the surface is completely clean and dry before applying any finish.Finishing Options:

Several types of finishes are suitable for outdoor wood furniture:Exterior Wood Stain:

Exterior wood stains penetrate the wood and add color while allowing the grain to remain visible. They provide some protection against moisture and UV damage. Choose a stain specifically formulated for outdoor use. Apply multiple coats according to the manufacturer's instructions. A topcoat of exterior varnish or sealant is recommended for added protection.Exterior Varnish:

Exterior varnish provides a durable and water-resistant coating that protects the wood from the elements. It is available in various sheens, from matte to gloss. Apply multiple coats of varnish, sanding lightly between coats for a smooth finish. Choose a varnish specifically formulated for outdoor use with UV inhibitors.Exterior Polyurethane:

Exterior polyurethane is a synthetic finish that provides a tough and durable coating. It is water-resistant and resistant to scratches and abrasion. Apply multiple coats of polyurethane, sanding lightly between coats. Choose a polyurethane specifically formulated for outdoor use with UV inhibitors.Spar Urethane:

Spar urethane is a type of polyurethane finish that is designed to be flexible and resistant to cracking or peeling in response to temperature changes and movement of wood. It is often used on boats and marine applications, making it a good choice for outdoor furniture.Penetrating Oil Finishes:

Penetrating oil finishes, such as teak oil or linseed oil, penetrate the wood fibers and provide some protection against moisture. They enhance the natural beauty of the wood and are easy to apply and maintain. However, they offer less protection than varnish or polyurethane and require more frequent reapplication. Consider using a UV protectant oil finish to improve resistance to sunlight.Paint:

Exterior paint can be used to create a solid color finish on the table top. Choose a high-quality exterior paint specifically formulated for wood. Apply a primer coat before painting to improve adhesion and coverage. Paint offers high UV resistance and colour flexibility but can obscure the natural wood grain.

Application:

Apply the chosen finish according to the manufacturer's instructions. Use a brush, roller, or spray gun, depending on the type of finish and your preference. Apply thin, even coats to avoid drips and runs. Allow each coat to dry completely before applying the next.Sealing End Grain:

End grain is more porous than the surface grain of the wood. Pay special attention to sealing the end grain to prevent moisture from penetrating and causing damage. Apply multiple coats of finish to the end grain, allowing each coat to soak in completely before applying the next.Maintenance:

Regularly inspect the table top for signs of damage or wear. Clean the table top with a mild soap and water solution. Reapply the finish as needed to maintain its protective properties. Store the table indoors or cover it with a waterproof cover during periods of inclement weather to extend its lifespan.

Diy Outdoor Table Angela Marie Made

Diy Outdoor Table Spoonful Of Imagination

Budget Friendly Diy 8 Foot Outdoor Table Simply Home

Make A Wood Patio Table Top For Your Old Frame Frugal Thumb

Diy Outdoor Table Free Plans Cherished Bliss

Make A Wood Patio Table Top For Your Old Frame Frugal Thumb

Diy Outdoor Table Free Plans Cherished Bliss

Diy Patio Table Top Fixing A Broken On Budget

Diy Patio Table Top Fixing A Broken On Budget

Slatted Outdoor Dining Table Build Diy 2x4 Patio Furniture

Related Posts